Elastomers - optimal freedom of design

Tinby offers a wide range of elastomer solutions - designed to meet the client's specific requirements. Elastomers, one of the main groups of plastics, are characterized by their extreme durability and elasticity when used at normal temperatures, and their ability to rapidly regain their original size and shape after they have been exposed to loads. Elastomers can be used for a multitude of products in many, different industries, as well as in everyday items.

The chemical explanation - in plain English

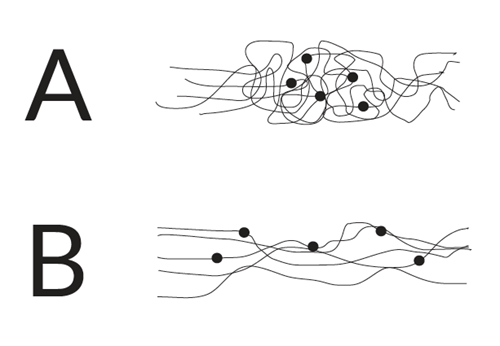

Polyurethane elastomers (or PUR elastomers/Polyurethane elastomers), are a combination of long chain-like molecules, or polymers, that are normally arranged randomly (illustration A). When subjected to heavy distortion (i.e. pressure or some other form of load) the polymer chains are stretched in the direction in which pressure is applied, whereupon the polymer chains fall into line towards the pressure source (illustration B). Once the pressure or load is removed, the polymer chains revert to their original, random arrangement. This means that no matter how many times the material is distorted, it will always revert to its original starting point.

The polymer chains can be stretched like this due to the high degree of elasticity. The polymer chains are linked by connectors which play a role in determining the degree of durability the elastomers have. Multiple connectors increase their durability, as they reduce the degree to which the polymer chains can move when subjected to pressure. As a simple illustration, you can compare the elastomer's chemical composition with a plate of spaghetti and meatballs: The polymer chains represent the spaghetti and the connectors are the meatballs.

What are the benefits of using elastomers?

Tinby's elastomers offer many benefits. Whether you take advantage of the elastomers' properties to manufacture a conveyor belt that is built to take dynamic (moving) loads, or something for static loads such as packages, elastomers are the ideal solution. As a supplier to several large, international wind turbine manufacturers, we have built up considerable expertise over the years in high-tech solutions using elastomers for, amongst others, industries such as the wind sector, which this material is also perfect for.

All of our solutions, which are all custom designed for each client's particular requirements, comply with the regulatory requirements of the industries we operate in. Our close cooperation and daily dialogue with our elastomer clients ensures that we are always at the forefront of new technological developments.

Benefits of Tinby's elastomer solutions are, among others:

- High durability

- High compression and tensile strength

- Low permanent distortion

- Excellent elasticity

- Outstanding durability and lifetime

- Chemical-resistant

- 50–90 Shore A

- Pigmentation option

- High recoil factor → less energy absorbed → longer lifetime

Elastomers equal optimal freedom of design

Elastomers can be used in a multitude of products and applications, which can also be processed further of desired. Our many years of expertise and know-how within the field of moulding polyurethanes means that we can shape a product to conform exactly to the client's wishes. You, the client, therefore have a great deal of influence on the finished product.

Thanks to the versatility of elastomers, it is only your imagination that sets the limit when it comes to what you can manufacture using this material, and some of its uses include:

- Wind turbine parts, such as leading Edge Protection

- The automotive industry, for items such as seals and gaskets

- Items for the navy industry (seawater resistant)

- Constructed components such as gears, wheels and belts

- Coatings for things such as floors, roofs, wires and cables

- Machine components and robots

- Clothing such as shoes and shoe soles