Sustainability

At SP Group we work systematically to reduce our environmental impact and promote great environmental responsibility. We do this by using environmentally-friendly technologies and materials through a certified environmental management system. SP Group is constantly working to reduce the group's environmental impact by seeking to reduce its consumption of water, electricity and heat. Thus, we are reducing our carbon emissions and optimize energy consumption. Our goal is also to contribute to environmental sustainability through our customers' use of SP Group's products.

Hence, more than 26 % of our revenue comes from the greentech industry that uses our products to

- Reduce energy consumption

- Produce renewable energy

Certificates

As part of Tinby's focus on the environmental impact, the company was certified in 2016 according to the international standard ISO 14001, which is a family of standards related to environmental management system that ensures that Tinby's processes, activities and competences are aimed at minimizing external environmental impacts. As a result, environmental impacts are identified and among these, planned improvements in environmental performance are prepared. In addition, the most significant environmental conditions are managed and monitored.

|

|

|

|

|

|

Ubiquitous

Tinby operates globally with the delivery of PUR solutions to the greentech industry in particular. With modern production facilities in Denmark, Poland, USA, Latvia and China, we have the opportunity to supply polyurethane solutions in large parts of the world. This allows us to reduce long transport routes and thus avoid unnecessary environmental impact as a result of carbon emissions during transport.

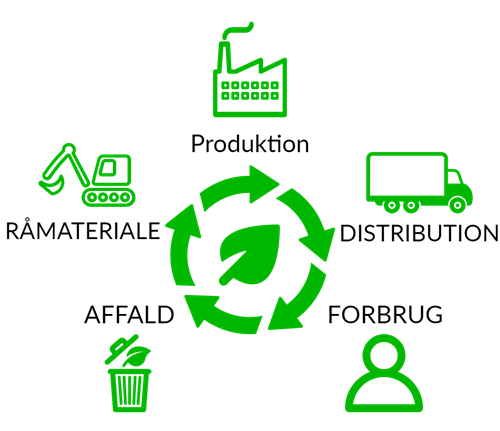

Life Cycle Assessment

In many ways, plastics are superior to most alternative materials in terms of strength, flexibility, weight and price. It is, among other things, lighter and more flexible than metal, which is why it is most often used as an alternative to metal in different industries. For example, plastic is used instead of metal on the exterior parts of rolling stock such as agricultural machinery, tractors, combine harvesters, buses and cars. This not only prolongs the durability of the material but also contributes to increasing the performance of the transport equipment and thus to reducing fuel consumption.

Waste management of flexible polyurethane

Unlike other types of plastics and especially other types of materials, polyurethane can be manufactured with very large variations in both density and stiffness, which is reflected in the great variety of products we are manufacturing for our customers. We all enjoy the amazing properties PUR provides but it presents us with some crucial challenges in terms of recycling. However, there are several ways to recycle PUR:

Mechanical recycling

- Rebonded foam - the most common method to process PUR: shredded PUR are shaped into new articles and sprayed using a specifically designed adhesive. The resulting rebounded foam is strong and versatile, making it extremely useful for new products such as carpets, sports mats, cushions etc.

- Widely used for the reuse of special mattresses.

Chemical recycling

- Another method consists of a chemical glucose process. Very simplified, the used PUR is transformed into a 'recycled polyol' from which it is possible to react with isocyanate. The recycled polyol has the same properties as a new or 'virgin' polyol and can thus be included in the production of new polyurethane products.

- This method involves the use of chemicals and energy and is therefore particularly useful in countries where waste management is typically carried out by landfill.

Energy recovery

- Polyurethane has a higher calorific value and can by controlled incineration be used for the production of electricity and district heating.

- Waste incineration is widely used in Northern European countries and is therefore an environmentally friendly alternative to mechanical and chemical recycling.

As an ISO-certified production company one of Tinby's main focus points is on the concept of circular economy. Circular economy aims at eliminating waste and preserving materials for as long as possible and with the highest possible value. Resources that would otherwise have ended up as waste are included in the production chain anew. The term 'waste' is being abolished, so to speak. We are thus spending resources on the training of staff in recycling and sorting tasks.

PURfection

Tinby is working with companies and researchers to develop a new method for recycling PUR products and waste - something that would otherwise simply end up at the landfill or incinerator plant. The new method will help reduce oil consumption and CO2 emissions. Read more about the project here.

Social sustainability

Tinby A/S collaborates with the workshop 'Grønnemoseværkstederne' in Svendborg on recycling of metal inserts used in the PUR casting for the purpose of being included in new products. The workshop employs approx. 160 people distributed across seven different workshops and offers a variety of possibilities such as employment, activities and socializing.

In addition, Tinby can pride itself on its collaboration with the municipality of Northern Funen in which we have employed a refugee who completed the basic integration education or 'IGU' at Tinby. The IGU aims to ensure that refugees obtain qualifications that provide the basis for either starting a vocational education or obtaining regular employment