Measuring chamber for hearing aids - in Polyurethane

High-tech audiological equipment

Benoto ApS is an innovative company dealing with the development of high-tech audiological equipment – from basic units to high-end products.

The company has customers all over the world. Tinby A/S has manufactured a range of different polyurethane cabinets for Benoto, which are, for instance, used as test environment for state-of-the-art audiological equipment.

Highly sensitive electronics

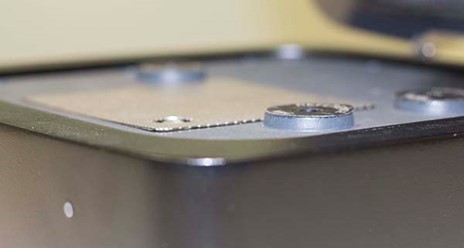

One of these cabinets is TBS10, a box that has been designed for the testing of hearing aids.

The cabinet was cast from rigid integral foam, which provides a soft core and a hard, non-porous surface. PUR is extremely resistant to external impacts and thus shields the sensitive electronics against ambient interference

Freedom of design

TBS10 consists of three parts, each cast in its own specially made aluminium mould. Each part has its own complex design details which ease the assembly of the box and give the test chamber a unique design and an elegant surface finish.

The parts are varnished in different colours, structures and lustres. This provides the cabinet with an aesthetic and functional appearance that matches the modern technology it is used for.

The items are cast in small series which is possible using polyurethane because of the rather low costs for production tools.