PULTRUDED COMPOSITE PROFILES

SCAFFOLDING PLATFORMS MANUFACTURED BY TINBY A/S FOR NORDIC PLATFORM P/S

Composite is a better material for making scaffolding platforms than wood, aluminium or steel! With that in mind, and with 20 years of experience in the scaffolding business, Per Mose Jakobsen, Managing Director of Nordic Platform P/S

began developing the product in collaboration with leading engineers in the field. Three years later, the product was ready to be manufactured and sold. The market reacted positively to the composite platform, which today can be found on numerous building sites throughout Scandinavia and the rest of Europe. Compared to other products on the market, the composite platform offers a large number of advantages in terms of the material, such as being lightweight, strong, maintenance-friendly and technologically-proven.

PRODUCTION IN LATVIA — CLOSE TO THE LOCAL MARKET

Since its inception, Nordic Platform has had their pultruded composite profiles produced in China, but in 2019 they reached a critical mass point in their production set-up which meant that an additional supplier was needed. And this is where Tinby’s manufacturing facilities in Latvia were chosen. Because the production is closer to the company’s local markets, it means that delivery time of platforms to Nordic Platform’s clients can be almost halved in comparison with manufacturing in China, while manufacturing in Latvia provides more opportunities and greater flexibility in regards to the order sizes and the number of tools in which the various platforms are produced.

WHAT IS PULTRUSION?

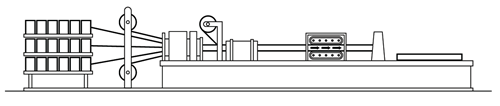

Pultrusion is a process in which a continuous flow of fibreglass is pulled through a tool that shapes the geometric cross-section into the desired profile. The fibreglass is impregnated with a resin, which then undergoes a thermosetting process creating a solid, shaped profile that can subsequently be sawn off into the desired lengths. This is also how Nordic Platform’s scaffolding platforms are manufactured at Tinby’s factory in Latvia.